Prodotti OEM / ODM

Individual designs

Our company engage in on and comprehensively implements individual designs of metal enclosures and power supply units according to the needs, specifications and designs submitted by our clients. The purpose for carrying out individual designs is to ensure client’s maximum satisfaction. Therefore, the rule we have approved as the basis of our activity is to meet our clients’ requirements so that they are fully satisfied with the product and contact with our company. As far as individual products are concerned, we are able to use various types of solutions.

Production capabilities - 360° visualization

Designing enclosures

Autodesk Inventor

3D design

3D PDF Converter

możliwość oglądania projeku w pdf w 3D

Autodesk AutoCAD

2D design

preparation for punching

Projektowanie zasilaczy - hardware / software

Altium Designer

projektowanie sprzętowe

Eclipse

programowanie software

Microsoft Visual Studio

programowanie software

Taglio

Possediamo i macchinari avanzati, tra cui le tagliatrici digitali che permettono di tagliare le costruzioni anche complicate nel diverso materiale, dipendentemante dale preferenze del cliente: Tipi di lamiera che utilizziamo:

lamiera in acciaio - 0,7mm ÷ 1,5mm

lamiera zincata - 0,7mm ÷ 1,5mm

lamiera in alluminio - 1mm ÷ 1,5mm

lamiera stagnata - 0,5mm (per gli schermi)

Colori

bianca RAL9003

bianca - struttura RAL 9003

griggia - struttura RAL 7035

beige - struttura RAL 1001

rosso - struttura RAL 3001

nero - struttura RAL 9005

altri colori su richiesta

Costruzione

tipo armadietto ”KO-1”

tipo a parete ”KO-2”

tipo a parete ”KO-3”

”KO-4”

tipo a parete -chiuso ”KO-5”

tipo RACK 19″ ”KO-6”

tipo a parete ”KO-7”

tipo ad incasso ”KO-8”

”KO-9”

”KO-10”

Opzioni di personalizzazione dei coperchi

fori per mikro switch, LED, LED e display LCD

incassi per LED

cablaggio di terra con il connettore singolo tipo ”UZ-1”

cablaggio di terra con il connettore doppio tipo ”UZ-2”

cablaggio di terra terra M4, M6 tipo ”UZ-3”

fori nel frontalino

serigrafia sul coperchio in vari colori RAL

adesivi

adesivi 3D

Cerniere

tipo MC-1 cerniere rimovibili

tipo MC-2 cerniere rimovibili aderenti

tipo MC-4 cerniere rivettate

tipo MC-5 cerniere avvitate

tipo MC-6 Sliding hinges with a spring

Chiusura del coperchio

tipo ZC-1 avvitato da sopra e dal lato

tipo ZC-2 avvitato dal lato (clip M3, M4)

tipo ZC-3 serratura metallica con chiave

tipo ZC-4 serratura di plastica senza chiave

tipo ZC-5 serratura di plastica con chiave

Distanziale dalla parete

distanziale di metallo

5mm tipo DS-1A

distanziale di plastica

11mm tipo DS-1B

distanziale di plastica

8mm tipo DS-2A

distanziale di plastica

14mm tipo DS-2B

distanziale di plastica

14mm tipo DS-2C

piedini per contenitori

tipo DS-3

– 8mm

tipo DS-4A

– 14mm

tipo DS-4B

– 5mm

tipo DS-5

distanziale a binario di metallo

tipo DS-6

distanziale a binario di metallo

tipo DS-7

distanziale di metallo 10mm

tipo DS-8A

distanziale di metallo 10mm

tipo DS-8B

Accessori

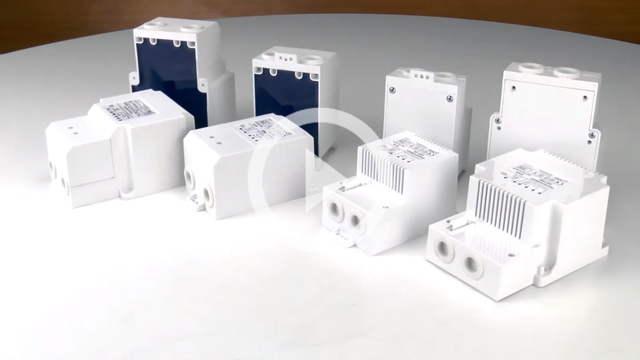

trasformatore serie TRP - IP30

trasformatore serie TRZ - IP43

trasformatore serie TOR

trasformatore serie EI

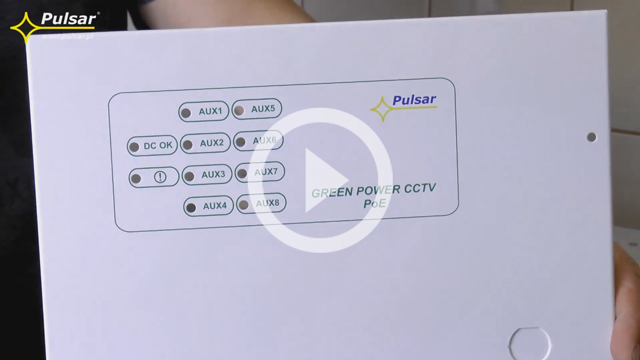

Alimentatori

Open frame

electronic modules

Alimentatori

su guida DIN

Mean Well Company

tamper

antiapertura

tipo TP-1

tamper

antiapertura tipo TP-2

tamper

antistrappo dalla parete

in contenitore di metallo tipo TP-3

tamper

antistrappo dalla parete

in contenitore di plastica tipo TP-4

tamper

tipo TP-5

morsettiera 12-poli 2,5 / 4 / 6 mm2

morsettiera 3 e 5-poli con il fusibile

elemento di montaggio saldato

pannello di montaggio con le cerniere

cablaggio di terra

canaline per i cavi

Mocowanie wyposażenia

fori + distanziali

perno distanziatore di plastica

agganci

montaggio degli agganci GE

bulloni filettati – FH

bulloni filettati saldati – ST

bulloni SMPS

tasselli filettati pressatinon passanti - BSO

tasselli filettati pressatipassanti - SO

tasselli filettati saldati - ST – ST

perno PCB per il montaggio

bulloni avvitati, esagonali M3x10

montaggio per il pannello di montaggio

montaggio per il pannello di montaggio

agganci tipo RACK

binario DIN avvitato

montaggio del pannello

montaggio del pannello

montaggio del pannello laterale

Ventilazione

„The „Gills” ventilation” – tipo WT-1

rettangolari – tipo WT-2

protezione del ventilatore – tipo WT-3

Introduzione dei cavi

passaggio di gomma Ø10

passaggio di gomma non passante Ø24

passaggio IP68, M20, M16, M12

pre-forature Ø29/22

pre-forature rotondi

pre-forature rettangolari

Fori / Imbottitura

fori rotondi, rettangolari

elissi

altri

altri

pre-foratura

pre- foratura per passaggio cavi

pre- foratura per la serratura

pre- foratura per antenne GSM

simbolo di messa a terra

nomi e numerazioni

logo

holes for plastic clamps

przetłoczenie pod opaski

przetłoczenie ograniczające

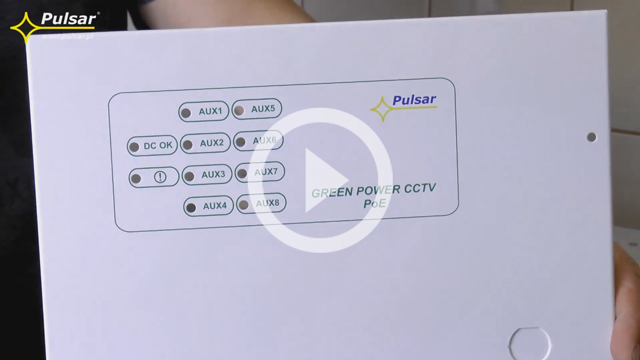

Przykładowe produkty obudów

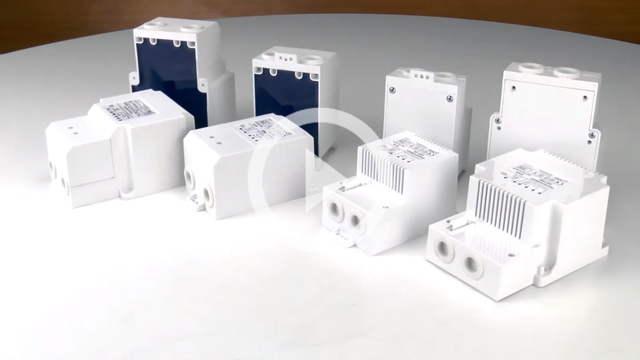

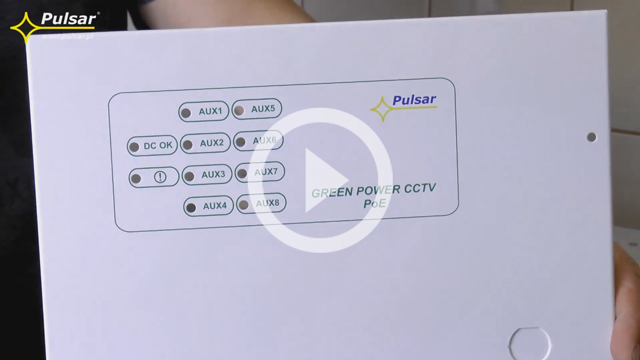

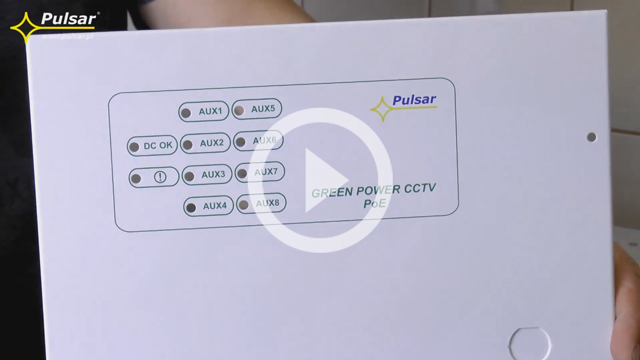

Przykładowe produkty zasilaczy

See how our products are made

Welcome to our website about the production of electronics and enclosures. Custom projects of electronics design, installation and comprehensive production of electronic devices (OEM and ODM). Our professional customer service has earned us the trust of customers in Poland and abroad. We are pleased to invite you to cooperate with our company.

Loading...

1. Designing

2. Automatic Screen Printer

3. Automatic SMD

4. Tunnel furnace

5. Through-hole technology

6. Soldering unit

7. Wire processing

8. The production of transformers

9. Electronics

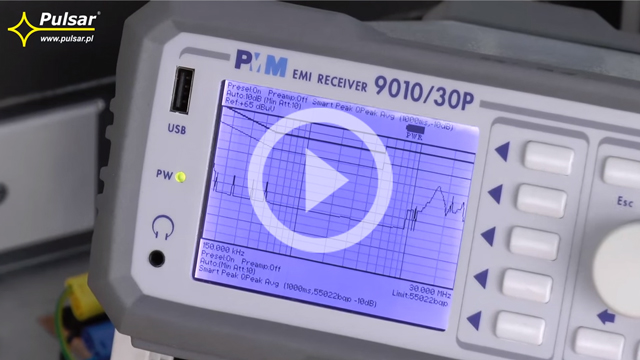

10. EMC Laboratory

11. Temperature test chamber

12. obudowy

13. Screen printing

14. Injection molding machines

15. 3D printer

16. Electronics assembly

17. Storage and Shipping

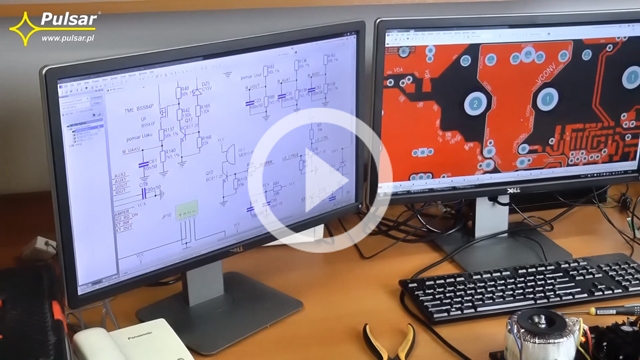

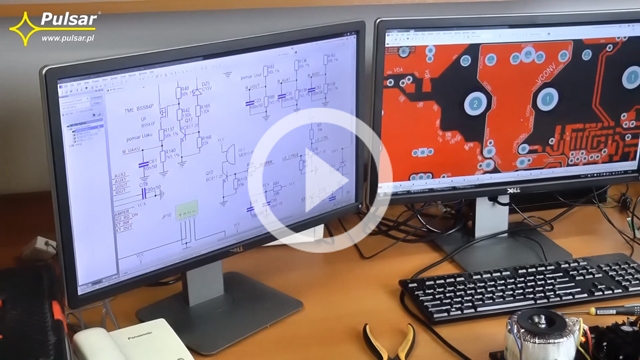

1. Designing

Our engineering staff designs complex electronic products. The design process involves many stages, of which the most important include the development of a schema, designing a PCB circuit (taking into account EMC requirements) and functional, thermal, and EMC testing. The design process is also based on integrated development environments, providing support in processor systems engineering and software design. We also offer technical advice, custom projects and professional service.

2. Automatic Screen Printer

The first step on the SMT (surface mount technology) assembly line is applying solder paste and/or glue on printed circuit boards. This process is carried out using the SR3100 screen printer manufactured by TWS Automation. Precise steel mesh along with the measurement of reference points allows the accurate adjustment of the position of the screen in relation to the PCB. The automated process for applying solder paste allows uniform coating of soldering points which is reflected in the quality of solders.

3. Automatic SMD

We offer professional mounting of SMD on printed circuit boards. The process is performed with the use of the modern, precise and highly efficient SAMSUNG SM482 SMD machine. The use of high-quality machine, strict production procedures, and our senior technicians guarantee the quality of our services. SMD or Surface Mount Electronic Components are placed in special containers, picked up from the feeders/tray by a system of nozzles and then placed on the appropriate pads on the PCB. The vision system allows to place individual components on the appropriate pads on the PCB with high precision. The minimum size of the components is 0402 (a rectangle of 1. 0mm x 0.5mm). The machine's performance reaches up to 28 000 SMD components per hour.

4. Tunnel furnace

The 1707 Mark III Series - SMT Reflow Oven is an essential element of SMT lines. It is a modern, convection tunnel klin with 7 heating zones. The solder paste is heated and melted in different zones of the furnace. In addition, loads (stresses) on the solders (SMD soldered to PCB pads) are also reduced. Conveyor System transporting PCB in the oven guarantees full control over the soldering process and process repeatability for each PCB.

5. Through-hole technology

In Through-Hole Technology, leads are soldered manually at individual workstations. It requires the appropriate assembly of components, iincluding: electrolytic capacitors, coils, inductors, diodes, and transistors with heatsinks. Then, wave soldering is used to soldering through-hole components on the bottom of PCB.

6. Soldering unit

PCBs are sent to a modern soldering unit by ATF. Then, the tin-plating of printed circuit boards and soldering through-hole components (through-hole technology – THT) on the bottom of PCBs, is performed. This leads to lead-free soldering in a nitrogen atmosphere. The use of nitrogen reduces oxidation and improves the quality of soldering. 90% of the soldering process is performed automatically, the remaining 10% is additional manual soldering.

7. Wire processing

The Gamma 263 S crimping machine by KOMAX enables fully automatic wire processing. The device precisely cuts wires to a desired length and allows one and two-sided crimping. The maximum cross-section of the processed cable is up to 4mm2 with cable lengths from 4 cm to 20 m. Full control of the quality of the crimped connector is ensured by the certified Universal Tester Model CT 50 by MAV PRÜFTECHNIK for tensile strength measurements. Indication range: 0-500 N.

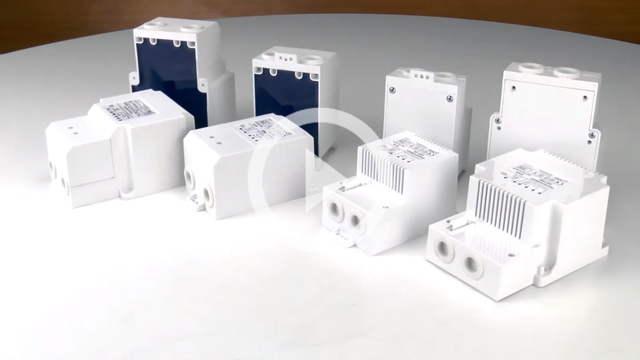

8. The production of transformers

Our company offers transformers of the following series: T (IP43), TRP (IP30), TOR, and EI with power ranging from 20 VA to 300 VA. Transformer enclosures (TRZ, TRP) are made of PC/ABS, UL 94 V-0 class. Transformers of the TRZ series, cast epoxy resin, IP43 protection class. In the final stage of the production process, transformers undergo a number of tests. These include, among others, high-voltage AC dielectric test and DC insulation resistance measurement using the certified MI 2094 CE Multitester by METREL.

9. Electronics

The next step in the production process is programming and testing of electronics. Firmware is uploaded to the module (microprocessor) and - after the calibration - electrical and software parameters and protection circuits are being tested. Properly selected test procedures guarantee that every electronics module leaving the production line has the same performance characteristics.

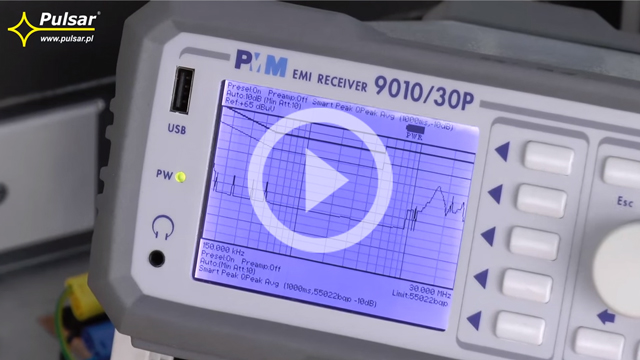

10. EMC Laboratory

The company owns and operates its own professional EMC laboratory. It allows - at the design stage or after completion of the works - to conduct research in the following areas:

- The measurement of conducted disturbances

- The Measurement of Harmonic Current

- Electrical fast transient/burst immunity test

- Electric and Magnetic Field Coupling to PCB

- and others

The company's ability to carry out immediate tests significantly shortens the process of designing electronic devices.

11. Temperature test chamber

12. obudowy

Production of enclosures is based on metal processing, starting from a clean sheet to packaging the final product. The company has the following departments: CNC Punching Department, Press Brake Department, Powder Coating Shop, and other departments supporting the production process. Control at every stage of manufacturing process, including design, cutting, crimping, or powder coating is the breason why all of our products are fully functional and free of defects. More than 20 years of experience and high-quality machinery allow us to meet the expectations of the most demanding customers.

13. Screen printing

The Pulsar Company offer custom graphics and screen printing on our products. The most commonly used method is screen printing, a printing technique whereby a mesh is used to transfer ink onto a substrate. Screen printing is also a stencil method of print making in which a design is imposed on a screen of polyester which is extremely durable and resistant to scratching.

14. Injection molding machines

Using injection molding machines by ARBURG, our company produces a whole range of plastics used for the production of electronics and housings. Injection molding machines along with a number of injection molds allows to produce spacers, mounting strips, and transformer enclosures.

15. 3D printer

16. Electronics assembly

Using injection molding machines by ARBURG, our company produces a whole range of plastics used for the production of electronics and housings. Injection molding machines along with a number of injection molds allows to produce spacers, mounting strips, and transformer enclosures.

17. Storage and Shipping

Production area, warehouses, and offices of our company cover an area of over 5000m2. Proper storage and packaging of products allows their adequate protection during transport. The vast majority of shipments is carried out by external professional transport companies. Compliance with the guidelines of the shipping company concerning the preparation of parcels and pallets allows for safe transport to our customers.

Loading...

1. Designing enclosures

2. Punching machines

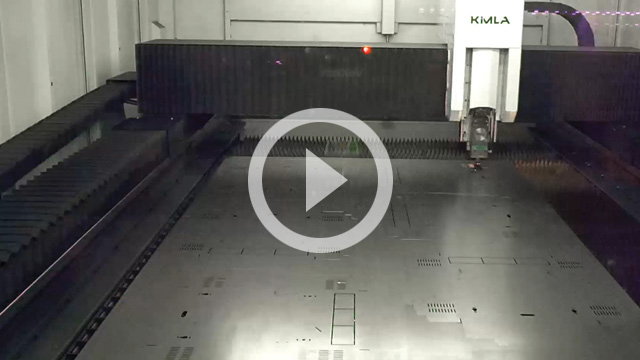

3. Laser

4. Hydraulic press

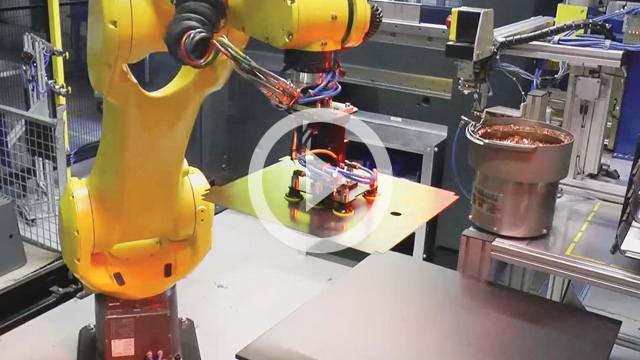

5. Robot

6. Electric resistance welding

Arc welding

7. Welding machine

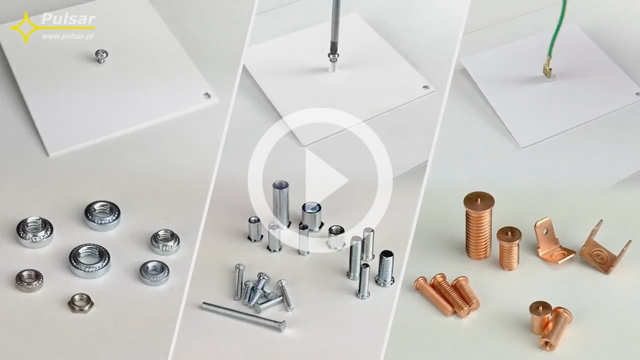

8. The production of SMPS connectors

9. Powder coating

10. Screen printing

11. Injection molding machines

12. 3D printer

13. The production of transformers

14. Wire processing

15. Mounting of enclosures

16. Tests

17. Storage and Shipping

1. Designing enclosures

Our engineering staff designs enclosures and housings for power supply units. The advanced software allows precise design of individual housing parts. The prototype is tested and modified several times before the product goes into mass production. We also offer technical advice, custom projects and professional service. We are using the following software:

- Autodesk Inventor - 3D Design

- Autodesk AutoCAD - 2D design - preparation for punching

- 3D PDF Converter - a 3D pdf of the project

In the case of already designed enclosure, we accept the following file types: .dwg, .dxf, .step, .ipt, and .iam.

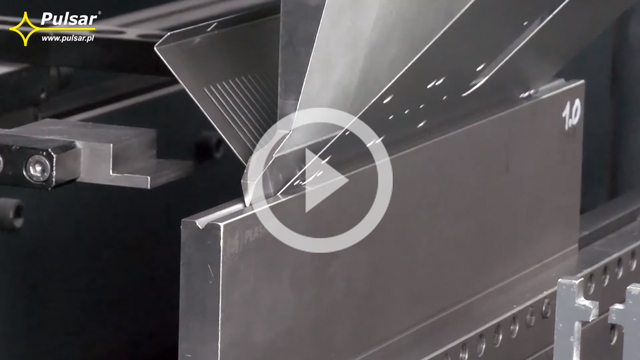

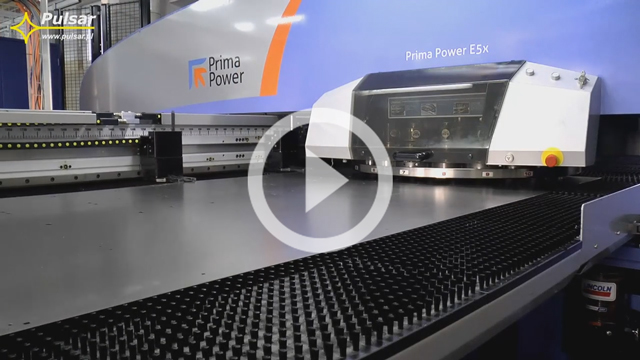

2. Punching machines

Finished enclosure projects are punched by CNC punching machines. These are cutting down the desired forms from metal sheets. Punching machines automatically move sheets, punching various kinds of holes, including: rectangle, circle, ellipse, and others - depending on the needs. The device also allows to punch pre-embossed openings by simultaneously cutting the desired shape and and embossing the sheet. In addition, there is the possibility of stamping serial numbers / names / symbols / logos on a given part of the enclosure. The use of CNC punching machines ensiures precise cutting and repeatability of elements.

3. Laser

4. Hydraulic press

The high quality and repeatability of our products is guaratnteed by the use of professional press brakes by SAFAN DARLEY. Their accuracy allows us to faithfully reproduce the project in the actual product. Their versatility allows the processing of sheets with a thickness of 0.5 ÷ 3 mm and lengths of up to 1.6 m. Simple operation allows to obtain high quality and repeatability of each designed element.

5. Robot

6. Electric resistance welding

Arc welding

Depending on the enclosure type and its operation conditions, different processes for welding and joining materials are being used. Welding and fusion welding are the most commonly used metods in our company. In the first case,work pieces are welded due to a combination of a pressure applied to them and a localized heat generated by a high electric current flowing through the contact area of the weld. When the current is stopped, the molten metal solidifies under pressure. Meanwhile, Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. The vast majority of enclosures is produced with use of Electric resistance welding due to lower costs and time involved.

7. Welding machine

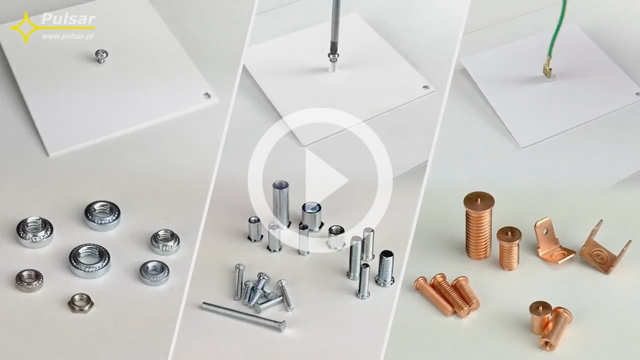

8. The production of SMPS connectors

We have dedicated equipment for the connection of small threaded pins, bushings or connectors. Bushings mounted in metal are automatically administered into the device and pressed with adequate pressure. In the case of grounding connectors, they are welded to steel sheets. These connections are durable and aesthetic, can be used to mount the PCB elecctronic modules in enclosures, for detachable connections of two steel elements or for grounding of housings or power supply units.

9. Powder coating

Before powder coating, the enclosures undergo a series of processes for the proper preparation of the surface. These include, among others, cleaning and protecting the surface with use of dedicated chemical solutions in ultrasonic baths. The next step is the protection of connectors and grounding terminals against painting. The painting process is performed in special ventilated booths using dedicated equipment suitable for powder coating. The final step is curing in an appropriate oven resulting in a durable and aesthetic coating. Several housings from each production batch are checked for the quality of the painted surface and paint thickness.

10. Screen printing

The Pulsar Company offer custom graphics and screen printing on our products. The most commonly used method is screen printing, a printing technique whereby a mesh is used to transfer ink onto a substrate. Screen printing is also a stencil method of print making in which a design is imposed on a screen of polyester which is extremely durable and resistant to scratching.

11. Injection molding machines

Using injection molding machines by ARBURG, our company produces a whole range of plastics used for the production of electronics and housings. Injection molding machines along with a number of injection molds allows to produce spacers, mounting strips, and transformer enclosures.

12. 3D printer

13. The production of transformers

Our company offers transformers of the following series: T (IP43), TRP (IP30), TOR, and EI with power ranging from 20 VA to 300 VA. Transformer enclosures (TRZ, TRP) are made of PC/ABS, UL 94 V-0 class. Transformers of the TRZ series, cast epoxy resin, IP43 protection class. In the final stage of the production process, transformers undergo a number of tests. These include, among others, high-voltage AC dielectric test and DC insulation resistance measurement using the certified MI 2094 CE Multitester by METREL.

14. Wire processing

The Gamma 263 S crimping machine by KOMAX enables fully automatic wire processing. The device precisely cuts wires to a desired length and allows one and two-sided crimping. The maximum cross-section of the processed cable is up to 4mm2 with cable lengths from 4 cm to 20 m. Full control of the quality of the crimped connector is ensured by the certified Universal Tester Model CT 50 by MAV PRÜFTECHNIK for tensile strength measurements. Indication range: 0-500 N.

15. Mounting of enclosures

The last stage of the production process of enclosures is the assembly line. At this stage, the product is finally assembled, tested and packaged. The ISO 9001:2008 quality management certificate is a guarantee that our customers receive fully functional and high quality products.

16. Tests

Metal sheet parameters, the weld strength, the thickness of paint coating, the grounding, and connector clamps are checked at every stage of the production of metal enclosures. The implementation of this type of control at each stage of the production process allows us to offer a 100% Customer Satisfaction Guarantee.

17. Storage and Shipping

Production area, warehouses, and offices of our company cover an area of over 5000m2. Proper storage and packaging of products allows their adequate protection during transport. The vast majority of shipments is carried out by external professional transport companies. Compliance with the guidelines of the shipping company concerning the preparation of parcels and pallets allows for safe transport to our customers.

If you're interested, please contact our sales department

Contatto